- Metal slice detecting

- Metallographic inspection

- Hardness test

- X-RAY

- Over tinned comparison

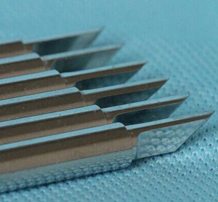

- Rotary swaging sample

Soldering tip made of copper as base material, surface plating with iron (Fe), nickel (Ni) and Chrome (Cr). The thickness and quality of the iron layer determines the life span of your soldering tip.

1. Our product with highly machine control level, which could ensure uniformity of iron layer thickness and stable service life. The products from low machine control level factory could have thin and un-uniform iron layer, which resulting in unstable service life.

2. Plating defects would cause low corrosion resistance of unit iron layer, which significantly decrease the service life of your soldering tip. Some factory increase the iron(Fe) layer thickness to 1 mm to raise life span, which would resulting in poor thermal conductivity and causing soldering defects on soldering point. We ensure 0.4mm iron thickness of our products, dense and no impurities, which are more resistant to corrosion

3. We use composite electroplating technology, which could improve 30% ability of the hardness and abrasion resistance than general electroplating technology.

4. We use Atotech hard Chrome plating solution. Chrome protect nickel from losing shine and minimize damage and corrosion. Maintain working area to stop over tinned after prolonged usage.Use general Chrome solution, soldering tip working area would be over tinned after long usage.

5. To assure that you can receive each product in precise dimensions from us. We use automatic CNC lathes to process basic copper material and strict quality control system. The external dimensions tolerance can reach to 0.05mm.Professional manufacturer can processing a complex product into one same product.